About the project

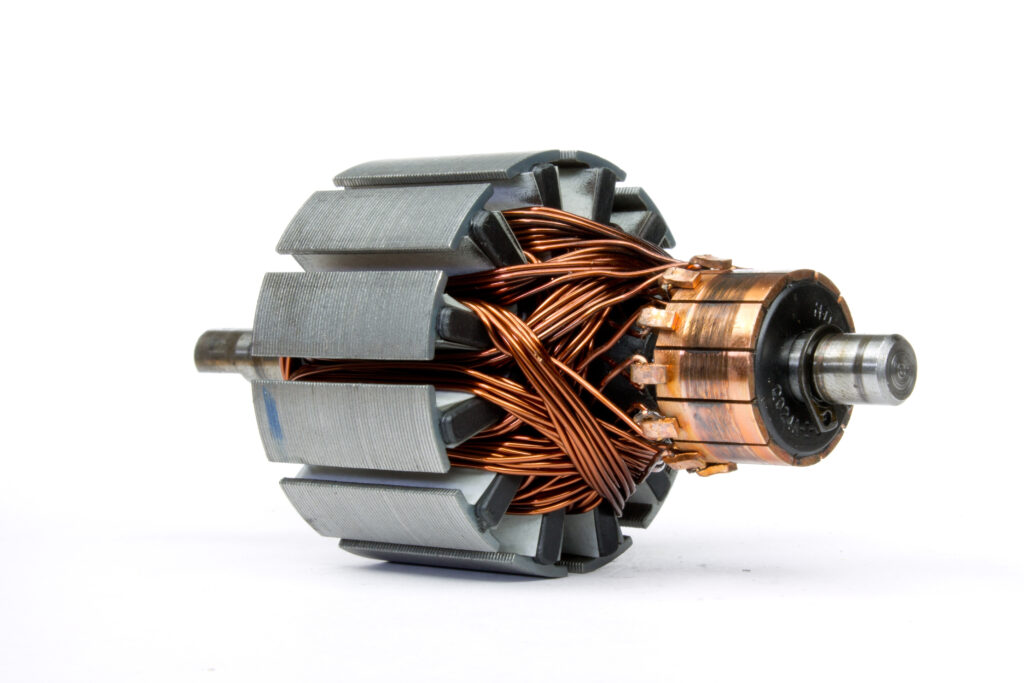

Additive Manufacturing for Electrical Machines (AM4EM) aims at integrating additively manufactured (AM) parts in the electromagnetic path of a machine: windings or elements of the stator/rotor core. To do so, there is a need for AM processes that are able to print multi-materials (MM). It involves combining the following materials in complex geometries:

- electrically conductive materials for guiding the current,

- magnetically conductive materials for guiding the magnetic flux and

- electrically isolating materials.

AM4EM will especially focus on combining two material sets during printing: electrically conductive combined with an insulator, and magnetically conductive combined with an insulator. Two similar AM processes – filament-based printing and robocasting – will be investigated, from the feedstock over the actual printing process to the post-processing (debinding & sintering).

At first, basic structures will be produced and tested in order to gradually improve the quality of the printed materials (e.g. related to electric conductivity, magnetic properties, density, … ). Consequently, new concepts for electrical machine parts that require more complex geometries will be evaluated.

The new EM concepts will on the one hand include the possibilities and limitations of the MM-AM process in terms of (e.g.) geometry and material properties. On the other hand, the MM-AM will be developed in view of realising structures for EM that cannot be produced using traditional manufacturing techniques.

AM4EM will deliver innovative MM-AM processes that can be applied for sensors, radars, actuators, electrical machines, etc. For the latter, AM4EM targets an increase in energy efficiency by 5%-point (compared to small induction machines) and an increase in power density by 40%.

Objectives & Goals

The main objective is to increase the power density of electric machines by 40% and the energy efficiency by 5%point (for small machines) by developing and leveraging on multi-material additive manufacturing (MM-AM). More particularly the project has set three subobjectives:

Objective #1

To develop, manufacture and validate innovative parts for EM for two concepts leveraging on MM-AM:

- Novel winding geometries for electrical machines based on Cu as conducting material and ceramic as electrical insulation material.

- Innovative stator and rotor core based, consisting of sheets isolated by a thin ceramic insulator.

Objective # 2

Develop MM-AM processes for high quality electrically conductive metals, magnetically conductive metals & ceramic insulators and their combinations, based on 3D micro-extrusion of powder filled paste and filaments with at least 40 vol% powder loading, and subsequent densification by powder metallurgical processing.

Objective # 3

Develop a “tool”chain to obtain AM parts of electric machines with accurate geometry, and required electromagnetic functionality.

The goal of the project is to move from TRL 2 to 4.